WEARABLE DANCE PRODUCT

Our design team set out to develop a wearable product for professional dancers that elevates their performance or fills a current market gap. The compiled research and data cover industry exploration, market segmentation, product testing, surveys & interviews, and data analysis. My team and I set out to research, design, and prototype a physical product within a sixteen week semester. This project allowed me to explore the dance industry, learn about performance clothing, team building, material research, and user led design.

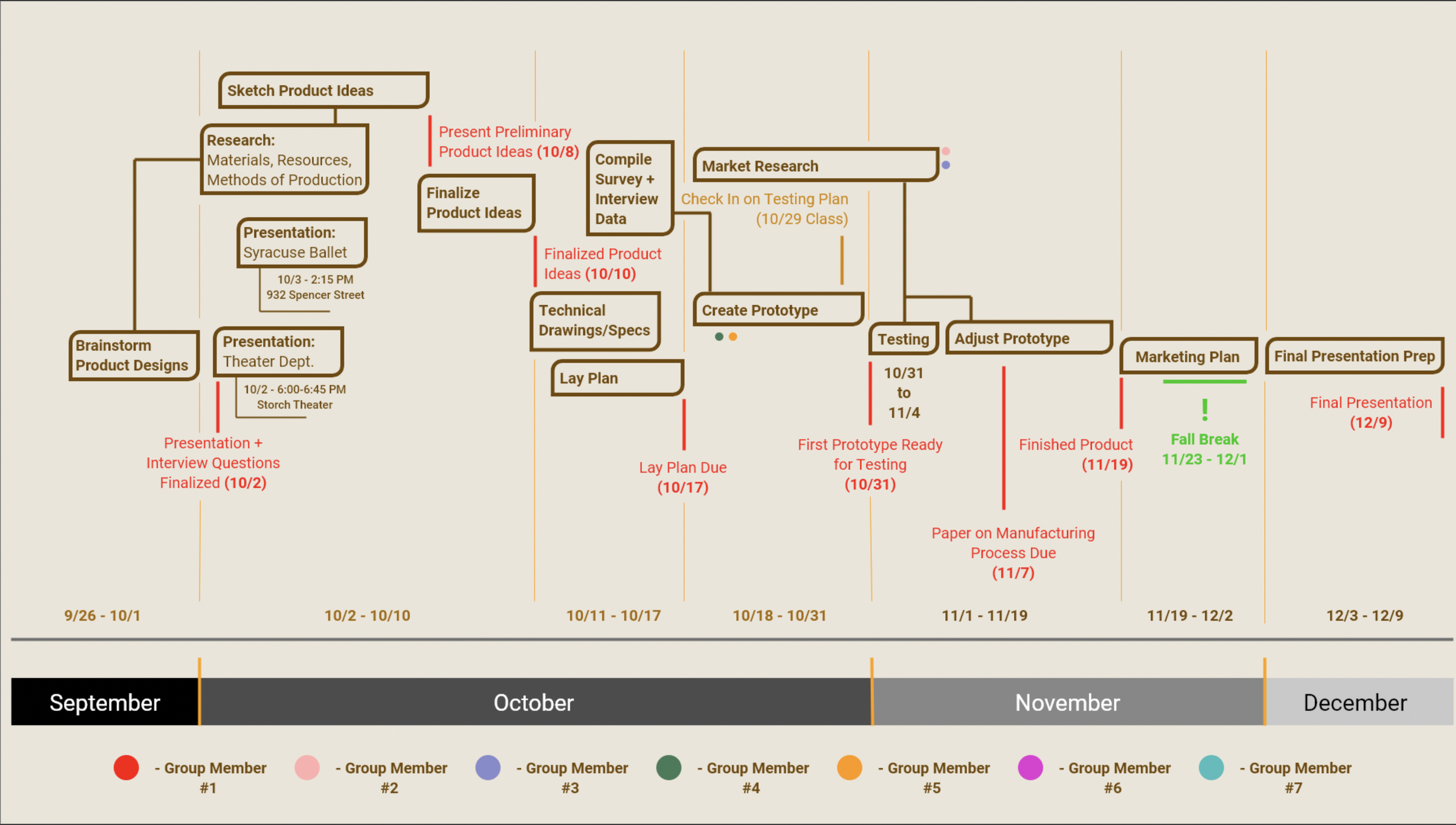

SUMMARY OF TIMELINE:

1. Preliminary research for a foundational understanding of the industry & market.

2. Analyze all research and formulate a concrete presentation.

3. Conduct interviews and surveys to gain personal feedback.

4. Use information gathered to create a product prototype.

5. Design, test, and perfect a final design.

DECEMBER 2019

MARKET SEGMENT

The following chart reflects the revenue makeup of the Dance industry and its individual

segment contributions from 2018.

It is evident that the market is almost entirely made up of dance class services (93.7%) equating to roughly 3.37 Billion of the 3.6 Billion market revenue. According to IBIS World, the total market revenue is projected to increase at an annualized rate of 2.5% for dance studios, reaching $4.1 billion by 2023. This is a big market to be tapped into. Especially considering that many niches within the market utilize dance-specific garments, ie. dance belts, leotards, pointe shoes, tights, compression fabrics, etc. Through various preliminary market research reports, our team has recognized a potential financial opportunity for a new wearable design in the dance industry.

DATA ANALYSIS

Based on the surveys and interviews, in addition to the initial research we conducted, our team decided that a pair of leggings that could heat and cool key areas on the lower body would be a useful wearable tool for dancers. We found that dancers usually spend long hours in the dance studio. Due to this as well as the general strain that dancing puts on the body we found that dancers are prone to injury, mostly in the lower body: feet, ankles, hips, or knees. Our survey and interview results supported what we discovered in our preliminary research, that dancers could benefit from a tool that reduces risk of injury. In many instances they do not have adequate time to recover from these injuries, therefore making themselves more vulnerable to future, potentially worse injuries. Our team decided that dance leggings would be a viable product due to the projected growth of the market. Designing heating/cooling leggings would be a low-matinence wearable to help keep dancer's muscles in peak shape.

PROTOTYPING

HEATING AND COOLING APPLICATION

Our team ideated various avenues of heating and cooling the inserts:

Electric; high cost, wiring challenges, no washability

Chemical; single use or boiled to return to room temperature

Plant-based; low cost, microwave, organic, washable

Gel: nonwashable, microwaveable

After collecting secondary research on each option, our team decided to pursue heat and cool testing in the plant-based category using flax seeds.

DURABILITY

Through secondary research, we discovered a heating/cooling pad that rapidly heats a gel substance. This option was attractive, however the user reviews revealed that the packs were bursting after a few uses. Since we expected to put these packs under physical stress, worn during physical activity, we moved on to other options. We began researching electric and alternative heating packs. Flaxseed became an attractive option as it has both cooling and heating properties and can heat up in a microwave. Furthermore, if the packs did undergo a lot of stress and broke over time, a hemp seed pack could be easily repaired by the dancer, who is used to doing hand repairs. Electric heating packs also show promise since electric outlets are more widely accessible than microwaves. Our team suggests more research should be done in this area, as it is a promising alternative to the hemp seed heat packs we researched.

FABRIC

In our material testing, we constructed samples in each of the materials listed below. We heated the packs at 1 minute each in the microwave. After, we set the packs aside and timed how long until each returned to room temperature. We also noted each material's temperature when it initially came out of the microwave. The image displays how the different samples compared. Based on our findings we decided to use a viscose wool blend; this material performed best for heating and cooling, and is a soft, thin fabric that feels polished and athletic. The double layered cotton material also proved to be a viable option; it is breathable and retains the heat as well as viscose. We suggest adding essential oils such as lavender to the fabric, or lavender fiber mixed with the flax seed for an added scent. Additionally, we decided to add an antimicrobial finish to the fabric to keep the packs from smelling after being exposed to sweat.

HEATING AND COOLING TESTING

The final heat & cooling insert is made using a fabric of 85% Viscose, 13% Wool, and 2% Spandex blend, single-layered. Vertical seam at a 1-inch spacing are added using a 100% cotton thread with a tight stitch (1-2). The channels of the ribbing are then filled with whole, untreated flax seed to 85% capacity (this allows for the top edge to be closed and the seeds to fill the insert without too much bulk). Finally, the top edge of the insert is surged closed with a wash tag and warning label. The inserts should be heated in the microwave on high for 2-5 minutes, or until desired heat level is reached. For cooling, they can be placed in the freezer for a minimum of 2 hours, or overnight.